Productive process

The productive process

All stages of production of the Gallo Plastic Bags

Quality control

The thickness (extrusion), dimensions (welding) and weight of each bag are constantly controlled. Certificated Quality Management System in compliance with the standards required by UNI EN ISO 9001:2008.

01

Distribution

After packaging, the bags are ready to be delivered by our own fleet or by accredited carriers.

02

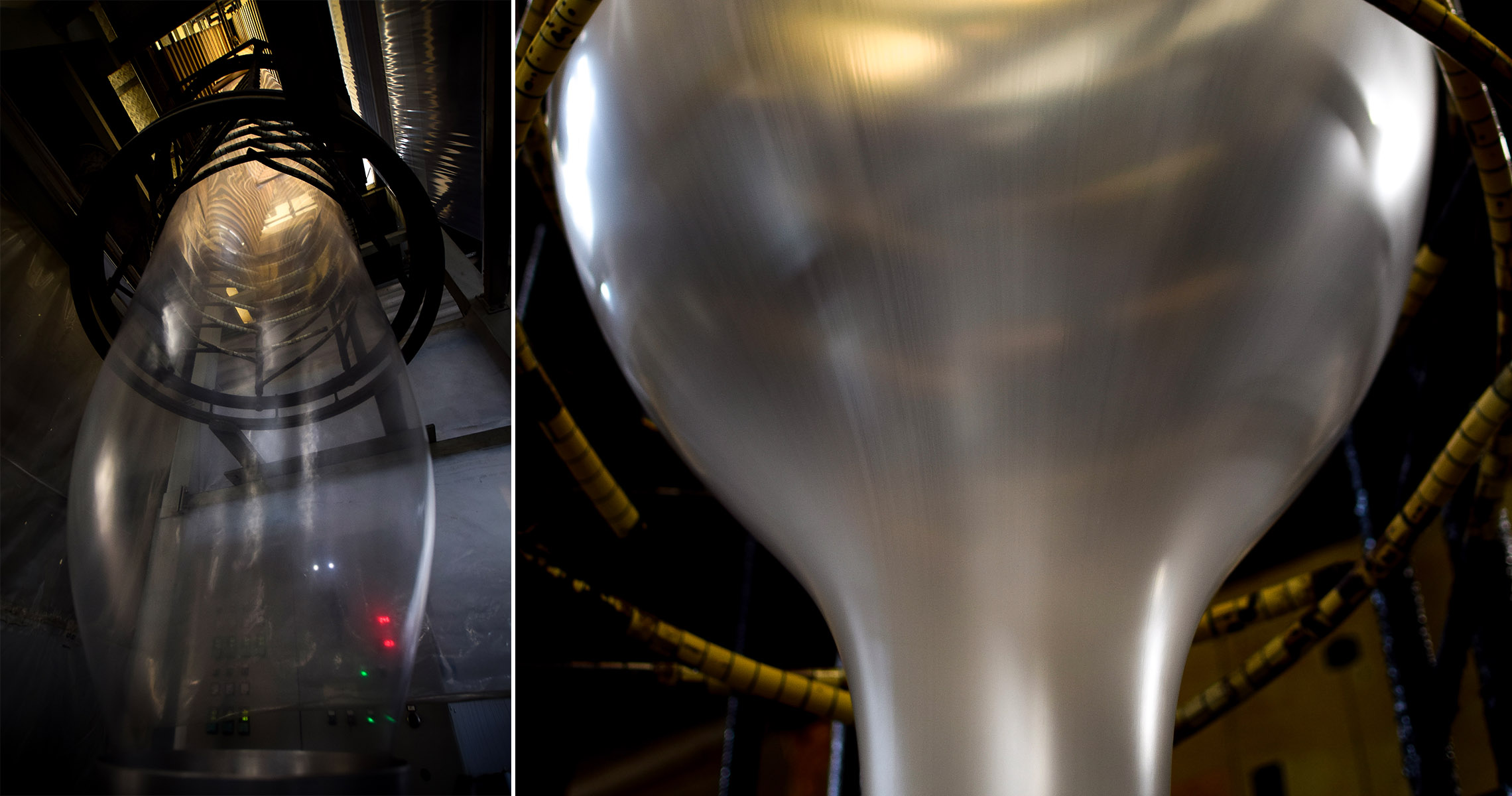

Extrusion

The multi-layer extrusion system ensures that the bag is tear-resistant. Polyethylene beads are melted then processed into rolls of film.

03

Research and development

Research into new technology materials, with particular attention to environmental protection; from the study of marketing strategies to pakaging design.

04

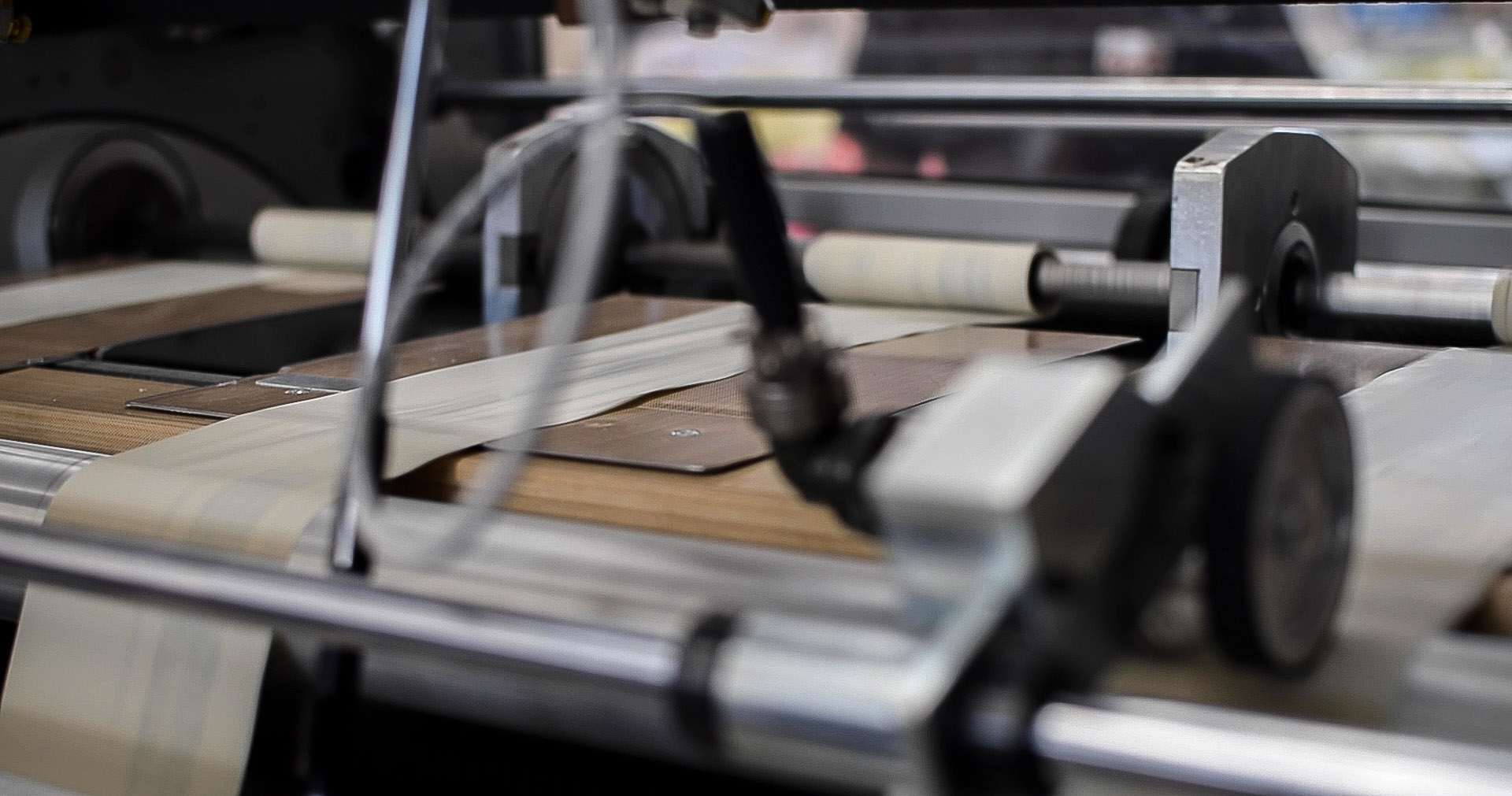

Welding and packing

From the roll, the bags are welded and precut to the required sizes. From the welding machine, the bundles or rolls of bags are automatically wrapped, packed and palletised.

05